MSJ Products List

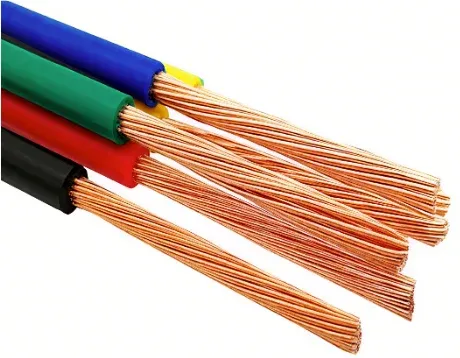

- Energy Storage Cable

- PVC Insulated Cable

- PV DC Cable

- Halogen-Free Cable

- Halogen-Free Cable

- High-Speed Copper Cable

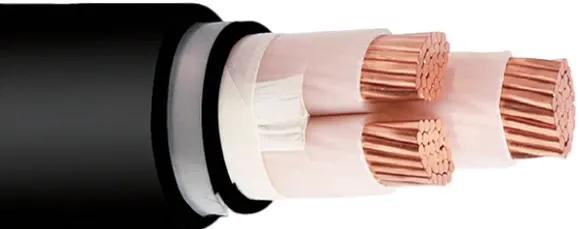

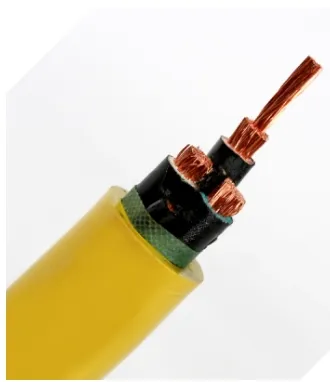

- Cu/PVC/PVC Power Cable

- LSZH Cable, Cross-Linked Polyolefin

- XLPE/PVC Power Cable

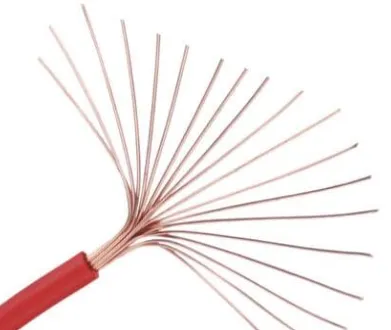

- BVR Cable

- BVV Cable

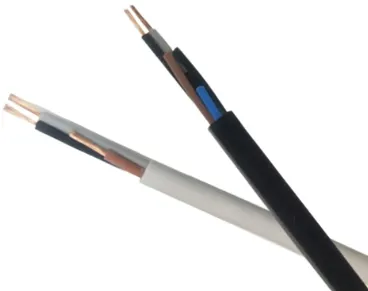

- BVVB Flat Cable

- KVV Cable

- PE/PVC Power Cable

- Prefabricated Substation

- Oil-Immersed Transformer

- Dry-Type Transformer

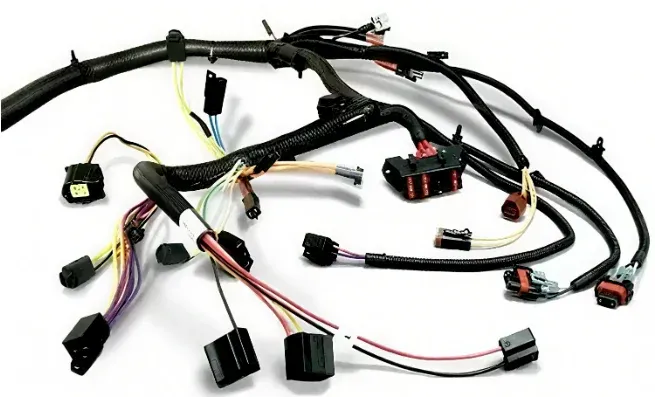

- Wire Harness and Connectors

Energy Storage Cable

(Energy storage)

Type: H07V-K / H07V-U

1. Product Application

Specialized for energy storage systems (e.g., energy storage power stations, residential energy storage, industrial & commercial energy storage). Used for power transmission, distribution and connection in AC circuits, compatible with core equipment like energy storage inverters and battery packs.

2. Product Ingredients

- Conductor: Bare copper, IEC 60228 Cl. 5, common cross-section 1.5-16mm²

- Stranded conductor OD: 3.0±0.1mm

- Insulation layer: Halogen-free PVC (HF-PVC)

- Insulation OD: 4.5±0.15mm

- Sheath layer: PVC sheath

- Overall cable OD: 5.7±0.2mm

3. Properties

- Conductor resistance (20°C): ≤ 4.95 Ω/km

- Insulation resistance(20℃): ≥500MΩ/km

- Insulation resistance (70℃): ≥0.3MΩ/km

- Voltage test: 2500 V, 5 min (AC), no breakdown

- Insulation thickness: IEC 60227

- Insulation tensile strength: ≥12MPa

- Insulation elongation: ≥150%

- Sheath tensile strength: ≥10MPa (wear-resistant, prolongs service life)

- Sheath elongation: ≥120%

- Flame retardancy: IEC 60332-1-2

- Rated voltage: 450/750V AC

- Rated frequency: 50/60Hz

4. Features

- Working temperature: -30℃~70℃

- Peak conductor temp: 90℃

- Bending radius: 6xD

- Service life: ≥30 years

- Current Rating Ambient Temperature: 40 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoid mechanical damage, stay away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

PVC Insulated Cable

(Indoor electrical installations)

Type: BV 1×4.0mm² 450/750V

1. Product Application

Suitable for power installations and fixed wiring with rated voltage 450/750V and below, applicable to dry or damp environments such as indoors, tunnels and pipelines.

2. Product Ingredients

- Conductor: Stranded copper (IEC 60228 Class 1), 19/0.52mm

- Insulation layer: PVC, nominal thickness 0.8mm, color: red/blue/yellow (optional)

- OD: 4.6±0.2mm

3. Properties

- Rated voltage: 450/750V

- Conductor dc resistance (20℃): ≤4.61Ω/km

- Insulation resistance (20℃): ≥100 MΩ·km

- Voltage test: AC 2.5 KV, 5min

- Insulation tensile strength: ≥12.5MPa

- Insulation elongation: ≥150%

- Minimum bending radius: 4×D

- Reference current-carrying capacity: 32A

4. Features

- Long-term operating temperature: 70℃

- Short-circuit temperature (5s): 160℃

- Installation temperature: ≥0℃

- Current Rating Ambient Temperature: 40°C

- Installation method: Free in air

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

PV DC Cable

(Solar farms)

Type: EN50618 : 2014 H1Z2Z2-K 1*4mm²

1. Product Application

- Internal connections: Connections between solar panels, between solar panels and combiner boxes, between combiner boxes and inverters, and other connections between devices within the system.

- External connections: Connections between the photovoltaic system and external related equipment.

2. Product Ingredients

- Conductor: Copper, stranded structure, 1*4mm²

- Inner insulation: LSZH cross-linked polyolefin

- Nominal Thickness: 0.85mm

- Jacket: XLPE (black/red)

3. Properties

- Conductor dc resistance @20℃: 5.09Ω/km(≤4.95Ω/km)

- Cable withstand voltage: 4.5kV AC/5min, no breakdown

- Rated voltage: DC 1.5/1.8 kV (to EN 50618)

- Dielectric Strength (AC): 6.5 KV/5min

- Operating temp: -40~+90 °C

- Bending radius: 6×D (outer diameter)

- Flame resistance: IEC 60332-1-2

- Avg. insulation thickness: 0.73mm(≥0.7mm)

- Outer insulation: LSZH cross-linked polyolefin

- Flame test: EN60332-1-2

- Smoke density: EN61034-2

- Halogen free: EN50525-1

- Ozone resistance: EN50396

- Oil resistance: EN60811

- UV resistant: EN60811-501

4. Features

- Maximum conductor temperature: 120℃

- Short-circuit temperature: 250℃, 5S

- Low-temperature impact condition: -40°C, stored for 16 hours (16h), compliant with EN 60811-506 standard

- Service life: ≥25 years

- Current Rating Ambient Temperature: 60 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 44A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

Halogen-Free Cable

(Photovoltaic systems)

Type: EN50618 : 2014 1x4.0mm² DC 1500V

1. Product Application

Suited for connecting photovoltaic system components inside and outside of buildings and equipment.

2. Product Ingredients

- Conductor: Stranded tinned copper (IEC 60228, Class 5); 52/0.30mm (mix0.295mm max0.30mm)

- Standard OD: 2.46mm

- Inner insulation: Halogen free crosslinked polyolefin Color: Black

- ID: 3.9±0.15mm

- Outer insulation: Halogen free crosslinked polyolefin Color: Black/Red

- OD: 5.7±0.2mm

3. Properties

- Maximum resistance of conductor at 20°C: ≤ 5.09 Ω/km

- Insulation resistance at 20°C: ≥580 MΩ km

- Insulation resistance at 90℃: ≥0.58 MΩ km

- Surface resistance of sheath: ≥109 Ω

- Voltage test of finished cable: AC 6.5KV 5min, No break

- DC voltage test of insulation: 1800V,240h(85℃,3%Nacl) No break

- Tensile strength of insulation: ≥10.3Mpa

- Elongation of insulation: ≥125%

- Tensile strength of sheath: ≥10.3Mpa

- Elongation of sheath: ≥125%

- Shrinkage resistance: ≤2%

- Acid and alkali resistant: EN 60811-404

- Ozone resistant: EN60811-403/EN50396-8.1.3

- UV-resistant: EN 50289-4-17

- Dynamic penetrate force: EN 50618-Annex D

- Winding at low temperature: EN 60811-504

- Impact at low temperature: EN 60811-506

- Fire performance: IEC60332-1-2

- Chlorine and bromine content: EN 50618

- Thermal endurance test: EN60216-1, EN60216-2, T120

4. Features

- Rated voltage: EN: DC1500V, AC1000V

- Working temperature: -40~90℃

- Max. conductor temperature: 120℃

- Short circuit temperature: 250℃ 5S

- Bending radius: 6xD

- Service life: ≥70 years

- Current Rating Ambient Temperature: 60 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 44A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoid mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

Halogen-Free Cable

(PV Systems)

Type: EN50618 : 2014 1x6.0mm² DC1500V

1. Product Application

This product is specialized for PV systems.

2. Product Ingredients

- Conductor: Stranded tinned copper (IEC 60228, Class 5; 74×0.30mm, with a mixed diameter range of mix0.295mm max0.30mm)

- Stranded OD: 3.0mm

- Inner insulation: Halogen free crosslinked polyolefin Color: Black

- ID: 4.5+0.15mm

- Outer insulation: Halogen free crosslinked polyolefin Color: Black/Red

- OD: 6.3 ± 0.2mm

3. Properties

- Maximum resistance of conductor at 20°C: ≤ 3.39 Ω/km

- Insulation resistance at 20°C: ≥500 MΩ km

- Insulation resistance at 90℃: ≥0.50 MΩ km

- Surface resistance of sheath: ≥Ω

- Voltage test of finished cable: Halogen free crosslinked polyolefin Color: Black/Red

- DC voltage test of insulation: 6.3 ± 0.2mm

- Tensile strength of insulation: ≥10.3Mpa

- Elongation of insulation: ≥125%

- Tensile strength of sheath: ≥10.3Mpa

- Elongation of sheath: ≥125%

- Shrinkage resistance: ≤2%

- Acid and alkali resistant: EN 60811-404

- Ozone resistant: EN60811-403/EN50396-8.1.3

- UV-resistant: EN 50289-4-17

- Dynamic penetrate force: EN 50618-Annex D

- Winding at low temperature: EN 60811-504

- Impact at low temperature: EN 60811-506

- Fire performance: IEC60332-1-2

- Chlorine and bromine content: EN 50618

- Thermal endurance test: EN60216-1, EN60216-2, T120

4. Features

- Rated voltage: EN: DC1500V, AC1000V

- Working temperature: -40~90℃

- Max. conductor temperature: 120℃

- Short circuit temperature: 250℃ 5S

- Bending radius: 6xD

- Service life: ≥70 years

- Current Rating Ambient Temperature: 60 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 70A, 67A, 57A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

High-Speed Copper Cable (Data centers)

Specification: EQSPPD4A-324CXX | Type: QSFP+ to QSFP+

1. Product Application

This is a passive direct-attach copper cable designed for Ethernet applications.

It is engineered for high-speed data transmission between servers and switches,

featuring a durable wired structure and individual packaging for ease of

deployment.

With excellent temperature tolerance and customizable length options, this cable

reliably supports modern data center and enterprise networking equipment where high-speed,

stable, and adaptable connectivity is essential.

2. Product Ingredients

- QSFP+ connectors

- Gold-plated pins

- Conductor material: Oxygen-free copper

- Shielding: Aluminum foil + copper braid

3. Properties

| Data rate | 40G |

| Operating voltage | 3.3V ±5% |

| Impedance | 100Ω ±10% |

| Dielectric withstand voltage | 1500V AC, 1 min |

| Insulation resistance | ≥1000MΩ @500V DC |

| Bend radius | Static: ≥30mm; Dynamic: ≥60mm |

| Tensile strength | ≥150N |

| Crush resistance | ≥1000N/100mm |

| Maximum length | 7m |

| Signal integrity | BER (bit error rate) < 1e-12 |

| Transmission distance | Up to 7m |

| Conductor material | 99.99% oxygen-free copper |

| Jacket material | Flame retardant PVC |

| Connector housing | Zinc alloy |

| Contact pins | Gold-plated (30u") |

4. Features

- Vibration resistance: 10g

- Return loss: > 15dB @ 25GHz

- Crosstalk: > 30dB @ 25GHz

- Compatibility: Fully compatible with IEEE 802.3ba and InfiniBand QDR specifications

- Total bandwidth: 40 Gb/s

- Channels: 4 independent duplex channels

- Data rates: 10 Gbps / 5 Gbps / 2.5 Gbps

- Power supply: Single 3.3 V

- Power consumption: < 1.5 W

- Operating temperature: -40°C - +85°C

- Cable size range: 24 AWG to 30 AWG

The product ensures precise signal synchronization with low transmission loss and minimal signal reflection, enabling efficient and stable data transfer.

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information

should be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container Type | Wooden box | Cable/wooden box | Total length (m) |

|---|---|---|---|

| 20ft | 100m | 20 | 192Roll / 384,000m |

| 40ft | 100m | 40 | 192Roll / 768,000m |

- Standard Length: 2 meters per rod/piece.

- Unit of Sale: Sold per rod/piece, Individual package.

- Custom lengths are available upon request.

6. Storage

- Inspection: Check cables quarterly. Look for insulation damage, loose/oxidized connectors, and surface dirt.

- Cleaning: Wipe surface contaminants with a dry cloth. Avoid corrosive cleaners.

- Connectors: Regularly check QSFP+ pins. Clean oxidation/dirt with swabs for good contact.

- Repairs: Fix minor insulation damage with standard tape. Replace cables if connectors are broken or speed drops below 40Gbps.

- Testing: Perform transmission testing every 6 months. Ensure transmission rate ≥40 Gbps, normal SNR, and no packet loss.

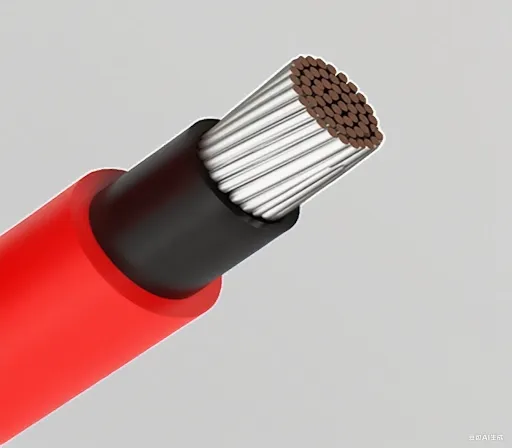

Cu/PVC/PVC Power Cable (Industrial power)

Type: VV 0.6/1kv 3*50+1*25

1. Product Application

Suitable for power transmission and distribution systems with a rated voltage up

to 0.6/1 kV. It is widely used in fixed installations such as industrial plants,

commercial buildings, municipal engineering, and residential complexes.

This cable is applicable for indoor, tunnel, cable trench, and direct burial environments.

It serves as power lines to connect distribution equipment, motors, transformers, and

other electrical devices.

2. Product Ingredients

- Conductor: Copper, stranded (to GB/T 3956, Class 1), 3×50mm² + 1×25mm²

- Insulation: PVC insulation, color-coded

- Sheath: PVC, black

- Overall diameter: ≈28.5 ±0.5mm

3. Properties

| Rated voltage | 0.6/1kV |

| Operating temp. | -15℃~+40℃ |

| Short-circuit temp. | ≤160°C (max 5s) |

| Bending radius | static: ≥6D; dynamic: ≥12D |

| Conductor resistance (20°C) | ≤0.38 Ω/km (50mm²); ≤0.72 Ω/km (25mm²) |

| Insulation resistance (20°C) | ≥1000 MΩ·km |

| Voltage test | 3kV/5min no breakdown |

| Insulation tensile strength | ≥12.5MPa |

| Insulation elongation | ≥125% |

| Sheath tensile strength | ≥12MPa |

| Sheath elongation | ≥150% |

4. Features

- Long-term operating temperature: 70℃

- Short-circuit temperature (5s): 160℃

- Halogen-free: meets IEC 60754 requirements

- Fire performance: complies with IEC 60332-1-2

- Service life: ≥70 years

- Current Rating Ambient Temperature: 40 ℃

- Installation method: Free in air, Buried in soil, Conduit, single

- Current rating: 130A, 120A, 110A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

High-Speed Copper Cable (Data centers)

Specification: EQSPPD4A-324CXX | Type: QSFP+ to QSFP+

1. Product Application

This is a passive direct-attach copper cable designed for Ethernet applications.

It is engineered for high-speed data transmission between servers and switches,

featuring a durable wired structure and individual packaging for ease of

deployment.

With excellent temperature tolerance and customizable length options, this cable

reliably supports modern data center and enterprise networking equipment where high-speed,

stable, and adaptable connectivity is essential.

2. Product Ingredients

- QSFP+ connectors

- Gold-plated pins

- Conductor material: Oxygen-free copper

- Shielding: Aluminum foil + copper braid

3. Properties

| Data rate | 40G |

| Operating voltage | 3.3V ±5% |

| Impedance | 100Ω ±10% |

| Dielectric withstand voltage | 1500V AC, 1 min |

| Insulation resistance | ≥1000MΩ @500V DC |

| Bend radius | Static: ≥30mm; Dynamic: ≥60mm |

| Tensile strength | ≥150N |

| Crush resistance | ≥1000N/100mm |

| Maximum length | 7m |

| Signal integrity | BER (bit error rate) < 1e-12 |

| Transmission distance | Up to 7m |

| Conductor material | 99.99% oxygen-free copper |

| Jacket material | Flame retardant PVC |

| Connector housing | Zinc alloy |

| Contact pins | Gold-plated (30u") |

4. Features

- Vibration resistance: 10g

- Return loss: > 15dB @ 25GHz

- Crosstalk: > 30dB @ 25GHz

- Compatibility: Fully compatible with IEEE 802.3ba and InfiniBand QDR specifications

- Total bandwidth: 40 Gb/s

- Channels: 4 independent duplex channels

- Data rates: 10 Gbps / 5 Gbps / 2.5 Gbps

- Power supply: Single 3.3 V

- Power consumption: < 1.5 W

- Operating temperature: -40°C - +85°C

- Cable size range: 24 AWG to 30 AWG

The product ensures precise signal synchronization with low transmission loss and minimal signal reflection, enabling efficient and stable data transfer.

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information

should be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container Type | Wooden box | Cable/wooden box | Total length (m) |

|---|---|---|---|

| 20ft | 100m | 20 | 192Roll / 384,000m |

| 40ft | 100m | 40 | 192Roll / 768,000m |

- Standard Length: 2 meters per rod/piece.

- Unit of Sale: Sold per rod/piece, Individual package.

- Custom lengths are available upon request.

6. Storage

- Inspection: Check cables quarterly. Look for insulation damage, loose/oxidized connectors, and surface dirt.

- Cleaning: Wipe surface contaminants with a dry cloth. Avoid corrosive cleaners.

- Connectors: Regularly check QSFP+ pins. Clean oxidation/dirt with swabs for good contact.

- Repairs: Fix minor insulation damage with standard tape. Replace cables if connectors are broken or speed drops below 40Gbps.

- Testing: Perform transmission testing every 6 months. Ensure transmission rate ≥40 Gbps, normal SNR, and no packet loss.

Cu/PVC/PVC Power Cable (Industrial power)

Type: VV 0.6/1kv 3*50+1*25

1. Product Application

Suitable for power transmission and distribution systems with a rated voltage up

to 0.6/1 kV. It is widely used in fixed installations such as industrial plants,

commercial buildings, municipal engineering, and residential complexes.

This cable is applicable for indoor, tunnel, cable trench, and direct burial environments.

It serves as power lines to connect distribution equipment, motors, transformers, and

other electrical devices.

2. Product Ingredients

- Conductor: Copper, stranded (to GB/T 3956, Class 1), 3×50mm² + 1×25mm²

- Insulation: PVC insulation, color-coded

- Sheath: PVC, black

- Overall diameter: ≈28.5 ±0.5mm

3. Properties

| Rated voltage | 0.6/1kV |

| Operating temp. | -15℃~+40℃ |

| Short-circuit temp. | ≤160°C (max 5s) |

| Bending radius | static: ≥6D; dynamic: ≥12D |

| Conductor resistance (20°C) | ≤0.38 Ω/km (50mm²); ≤0.72 Ω/km (25mm²) |

| Insulation resistance (20°C) | ≥1000 MΩ·km |

| Voltage test | 3kV/5min no breakdown |

| Insulation tensile strength | ≥12.5MPa |

| Insulation elongation | ≥125% |

| Sheath tensile strength | ≥12MPa |

| Sheath elongation | ≥150% |

4. Features

- Long-term operating temperature: 70℃

- Short-circuit temperature (5s): 160℃

- Halogen-free: meets IEC 60754 requirements

- Fire performance: complies with IEC 60332-1-2

- Service life: ≥70 years

- Current Rating Ambient Temperature: 40 ℃

- Installation method: Free in air, Buried in soil, Conduit, single

- Current rating: 130A, 120A, 110A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

LSZH Cable, Cross-Linked Polyolefin (Fire-safe buildings)

Type: WDZ(A、B、C)-BYJ 2.5mm²

1. Product Application

Suitable for high-rise buildings, subways, underground streets, large shopping

malls, hospitals, large power stations and important industrial and mining

enterprises and other places related to fire safety and rescue.

Used as power transmission lines in environments requiring low smoke, halogen-free,

flame-retardant and fire-resistant performance during combustion.

2. Product Ingredients

- Conductor: High-purity stranded copper wire (compliant with IEC 60228), ensuring excellent conductivity

- Insulation layer: Excellent insulation performance, low smoke and halogen-free

3. Properties

| Conductor dc resistance (20°C) | ≤4.0Ω/km |

| Insulation resistance (20℃) | ≥1000 MΩ·km |

| Finished product withstanding voltage | AC 3.5kV, 5min no breakdown |

| Insulation tensile strength | ≥12.0MPa |

| Insulation elongation | ≥150% |

| Sheath tensile strength | ≥11.0MPa |

| Halogen-free performance | Halogen content ≤0.5% (EN 50618) |

| Low-smoke performance | Light transmittance ≥80% (IEC 61034) |

| Service life | ≥30 years (under normal service conditions) |

4. Features

- Maximum rated conductor temperature: 90℃

- Short-circuit temperature: 250℃

- Installation temperature: ≥0℃

- Current Rating Ambient Temperature: 40 ℃

- Installation method: Free in air, Underground direct burial (25℃ soil)

- Current rating: 65A, 58A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

XLPE/PVC Power Cable (Building power)

Type: YJV 0.6/1kV 4*95+1*50

1. Product Application

Suitable for power transmission and distribution in industrial and civil

buildings, such as factories, residential communities, commercial complexes, etc.

Applicable to fixed laying in indoors, tunnels, cable trenches, and underground (not

immersed in water for long-term).

Ideal for power supply systems with AC 0.6/1kV, connecting equipment like transformers,

switchgears, and motors.

2. Product Ingredients

- Conductor: Copper, 4*95 + 1*50 mm², class 2

- Insulation: XLPE, color-coded as per standard

- Sheath: PVC, black

- Sheath thickness: 2.2 ± 0.2 mm

- Overall diameter: ≈40 ±1mm

3. Properties

| Rated voltage | 0.6/1kV(AC) |

| Operating temp. | -40~90℃ |

| Short-circuit temp. | 250℃/5s |

| Bending radius | ≥12×OD |

| Conductor resistance (20°C) | ≤0.193Ω/km (95mm²); ≤0.387Ω/km (50mm²) |

| Insulation resistance (20°C) | ≥1000 MΩ·km |

| AC voltage test | 3kV, 5min no breakdown |

| Insulation tensile strength | ≥12.5MPa |

| Insulation elongation | ≥125% |

| Sheath tensile strength | ≥12MPa |

| Sheath elongation | ≥150% |

| Chemical resistance | per EN 60811-404 |

| Ozone resistance | per EN 60811-403 |

| Flame retardancy | IEC 60332-1-2 |

4. Features

- Long-term operating temperature: 70℃

- Short-circuit temperature: 160℃/(5s)

- Installation temperature: ≥0℃

- Service life: ≥30 years

- Current Rating Ambient Temperature: 40 ℃

- Installation method: Free in air, Buried in soil

- Current rating: 250A, 200A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and corrosion-resistant. Common materials include moisture-proof paper, foam, and aluminum foil. Cable specifications, models, length, and other information should be clearly marked on the outside of the packaging. It's forbidden to store in open-air. During transportation, it must ensure that the cable reel is not dropped from the top or is damaged mechanically. It can be transported by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

BVR Cable (≤450/750V, PVC) Cabling System

Type: GB/T 5023 - 2008 BVR 1×2.5, BVR 1×4

1. Product Application

Specialized for fixed wiring in AC 50/60Hz electrical systems with rated voltage ≤450/750V, such as residential buildings, commercial complexes, industrial workshops, and electrical equipment internal wiring.

2. Product Ingredients

- Conductor: Stranded bare copper (IEC 60228, Class 1/2/5); strand count & diameter vary by conductor cross-section (e.g., 1.5mm²: 19×0.31mm; 2.5mm²: 19×0.41mm)

- Stranded OD: Varies by cross-section (e.g., 1.5mm²: ≈1.8mm; 4mm²: ≈2.6mm)

- Inner insulation: PVC (Polyvinyl Chloride) resin; Color: Black/White/Red/Yellow/Green (customizable)

- Outer insulation: Complies with GB/T 5023.3, min. thickness varies by cross-section (e.g., 1.5mm²: ≥0.7mm; 4mm²: ≥0.8mm)

- OD: Varies by cross-section (e.g., 1.5mm²: ≈3.2mm; 4mm²: ≈4.2mm)

3. Properties

| Conductor DC Resistance (20℃) | ≤12.1Ω/km (1.5mm²); ≤7.41Ω/km (2.5mm²); ≤4.61Ω/km (4mm²) (complies with IEC 60228) |

| Insulation Resistance (20℃) | ≥100MΩ·km |

| Insulation Voltage Test | AC 2000V, 5min, no breakdown |

| Insulation Tensile Strength | ≥12.5MPa (original); ≥8.5MPa (after thermal aging) |

| Insulation Elongation at Break | ≥150% (original); ≥100% (after thermal aging) |

| Thermal Endurance | Long-term working temp: -15~70℃; max. conductor temp under overload: 105℃ (short-term) |

| Flame Retardancy | Complies with GB/T 18380.1-2001 (vertical flame test) |

| Acid & Alkali Resistance | Resistant to dilute acid/alkali (per EN 60811-404) |

| Bending Radius | ≥4×cable OD (fixed installation); ≥6×cable OD (mobile installation) |

4. Features

- Rated Voltage: ≤450/750V AC

- Flexibility: Good bending performance, suitable for narrow/complex wiring spaces

- Current Rating: 1.5mm²: 20A; 2.5mm²: 28A; 4mm²: 40A (free in air)

- Service life: ≥20 years (under normal working conditions)

- Current Rating Ambient Temperature: 30 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

BVV Cable (≤300/500V, PVC) Fixed Installation

Type: GB/T 5023-2008 EN50618 : 2014 1x6.0mm² DC1500V

1. Product Application

Specialized for fixed wiring in AC 50/60Hz low-voltage electrical systems with rated voltage ≤300/500V, such as residential indoor wiring, commercial office power distribution, household electrical appliance internal connections, and small-scale industrial equipment wiring.

2. Product Ingredients

- Conductor: Solid/bare copper (IEC 60228, Class 1); conductor cross-section range: 0.75mm²~10mm² (e.g., 2.5mm²: single wire diameter ≈1.78mm)

- Stranded OD: Varies by cross-section (e.g., 1.5mm²: ≈1.38mm; 4mm²: ≈2.25mm)

- Inner insulation: PVC (Polyvinyl Chloride) resin; Color: Black/White/Red/Yellow-Green (grounding, mandatory color)

- Insulation Thickness: Complies with GB/T 5023.3, min. thickness: 0.5mm (0.75mm²) ~ 1.0mm (10mm²)

- Outer Sheath: PVC resin; Color: Black (standard) / White (customizable); Sheath thickness: ≥0.6mm (0.75mm²) ~ ≥1.2mm (10mm²)

- OD: Varies by cross-section (e.g., 2.5mm²: ≈4.8mm; 4mm²: ≈5.5mm)

3. Properties

| Conductor DC Resistance (20℃) | ≤22.8Ω/km (0.75mm²); ≤13.7Ω/km (1.5mm²); ≤8.61Ω/km (2.5mm²) (complies with IEC 60228) |

| Insulation Resistance (20℃) | ≥200MΩ·km |

| Insulation Voltage Test | AC 1500V, 5min, no breakdown |

| Insulation Tensile Strength | ≥12.5MPa (original); ≥8.5MPa (after thermal aging) |

| Insulation Elongation at Break | ≥150% (original); ≥100% (after thermal aging) |

| Thermal Endurance | Long-term working temp: -15~70℃; max. conductor temp under overload: 105℃ (short-term) |

| Flame Retardancy | Complies with GB/T 18380.1-2001 (vertical flame test) |

| Acid & Alkali Resistance | Resistant to dilute acid/alkali (per EN 60811-404) |

| Bending Radius | ≥4×cable OD (fixed installation); ≥6×cable OD (mobile installation) |

4. Features

- Rated Voltage: ≤300/500V AC

- Flexibility: Good bending performance, suitable for narrow/complex wiring spaces

- Current Rating: 1.5mm²: 20A; 2.5mm²: 28A; 4mm²: 40A (free in air)

- Service life: ≥20 years (under normal working conditions)

- Current Rating Ambient Temperature: 30 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

BVVB Flat Cable (≤300/500V, PVC) Exposed Cabling in Residential Buildings

Type: GB/T 5023.4-2008 BVVB 2×1.5mm² 300/500V

1. Product Application

Specialized for fixed flat wiring in AC 50/60Hz low-voltage electrical systems with rated voltage ≤300/500V, such as residential indoor wall/floor concealed wiring, commercial office narrow-space distribution, household appliance (e.g., air conditioner, water heater) power connections, and small-scale industrial equipment flat-layout wiring.

2. Product Ingredients

- Conductor: Stranded tinned copper (IEC 60228, Class 5; 840×0.285mm, mixed diameter 0.277mm to 0.293mm max)

- Conductor OD per Core: Varies by cross-section (e.g., 1.5mm²: ≈1.38mm; 2.5mm²: ≈1.78mm)

- Inner insulation: PVC resin; Color: Red/Black (2C) / Red/Black/Yellow-Green (3C, grounding core)

- Insulation Thickness: Complies with GB/T 5023.4, min. thickness: 0.5mm (0.75mm²) ~ 0.8mm (6mm²)

- Outer Sheath: PVC resin; Color: Black (standard) / White (customizable); Flat sheath size (2C×2.5mm²): ≈10.5×5.0mm (L×W)

- Cable Overall Size: Varies by core count & cross-section (e.g., 3C×1.5mm²: ≈12.0×5.2mm; 2C×4mm²: ≈13.2×5.8mm)

3. Protection Performance Properties

| Conductor DC Resistance (20℃) | ≤22.8Ω/km (0.75mm²); ≤13.7Ω/km (1.5mm²); ≤8.61Ω/km (2.5mm²) (complies with IEC 60228) |

| Insulation Resistance (20℃) | ≥200MΩ·km |

| Insulation Voltage Test | AC 1500V, 5min, no breakdown |

| Insulation/Sheath Tensile Strength | ≥12.0MPa (original); ≥8.0MPa (after thermal aging) |

| Insulation/Sheath Elongation at Break | ≥150% (original); ≥100% (after thermal aging) |

| Thermal Endurance | Long-term working temp: -10~60℃; Max. conductor temp under overload: 105℃ (short-term, ≤5s) |

| Flame Retardancy | Complies with GB/T 18380.1-2001 (vertical flame test, no continuous burning) |

| Sheath Abrasion Resistance | No sheath damage after 100 cycles of abrasion test (per EN 60811-203) |

| Bending Radius | ≥6×cable width (fixed installation); ≥8×cable width (temporary movement) |

4. Features

- Rated Voltage: ≤300/500V AC

- Service Life: ≥15 years (under normal indoor working conditions)

- Current Rating (Ambient Temp 30℃): 1.5mm²: 16A; 2.5mm²: 25A; 4mm²: 32A (free in air)

- Protection Performance: Double-layer protection (PVC insulation + PVC sheath), good moisture/abrasion resistance

- Current Rating Ambient Temperature: 30 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoided mechanical damage, stayed away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

BVVB Flat Cable (≤300/500V, PVC) Exposed Cabling in Residential Buildings

Type: GB/T 5023.4-2008 BVVB 2×1.5mm² 300/500V

1. Product Application

Specialized for fixed flat wiring in AC 50/60Hz low-voltage electrical systems with rated voltage ≤300/500V, such as residential indoor wall/floor concealed wiring, commercial office narrow-space distribution, household appliance (e.g., air conditioner, water heater) power connections, and small-scale industrial equipment flat-layout wiring.

2. Product Ingredients

- Conductor: Stranded tinned copper (IEC 60228, Class 5; 840×0.285mm, mixed diameter 0.277mm to 0.293mm max)

- Conductor OD per Core: Varies by cross-section (e.g., 1.5mm²: ≈1.38mm; 2.5mm²: ≈1.78mm)

- Inner insulation: PVC resin; Color: Red/Black (2C) / Red/Black/Yellow-Green (3C, grounding core)

- Insulation Thickness: Complies with GB/T 5023.4, min. thickness: 0.5mm (0.75mm²) ~ 0.8mm (6mm²)

- Outer Sheath: PVC resin; Color: Black (standard) / White (customizable); Flat sheath size (2C×2.5mm²): ≈10.5×5.0mm (L×W)

- Cable Overall Size: Varies by core count & cross-section (e.g., 3C×1.5mm²: ≈12.0×5.2mm; 2C×4mm²: ≈13.2×5.8mm)

3. Protection Performance Properties

| Conductor DC Resistance (20℃) | ≤22.8Ω/km (0.75mm²); ≤13.7Ω/km (1.5mm²); ≤8.61Ω/km (2.5mm²) (complies with IEC 60228) |

| Insulation Resistance (20℃) | ≥200MΩ·km |

| Insulation Voltage Test | AC 1500V, 5min, no breakdown |

| Insulation/Sheath Tensile Strength | ≥12.0MPa (original); ≥8.0MPa (after thermal aging) |

| Insulation/Sheath Elongation at Break | ≥150% (original); ≥100% (after thermal aging) |

| Thermal Endurance | Long-term working temp: -10~60℃; Max. conductor temp under overload: 105℃ (short-term, ≤5s) |

| Flame Retardancy | Complies with GB/T 18380.1-2001 (vertical flame test) |

| Sheath Abrasion Resistance | No sheath damage after 100 cycles (per EN 60811-203) |

| Bending Radius | ≥6×cable width (fixed installation); ≥8×cable width (temporary movement) |

4. Features

- Rated Voltage: ≤300/500V AC

- Service Life: ≥15 years (normal indoor environment)

- Current Rating (Ambient Temp 30℃): 2C×1.5mm²: 16A; 2C×2.5mm²: 25A; 3C×4mm²: 32A (free in air)

- Structural Advantage: Flat shape, small installation space occupation; suitable for narrow/concealed wiring scenarios

- Protection Performance: Double-layer PVC protection (insulation + sheath), good moisture/impact resistance

- Current Rating Ambient Temperature: 30 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoid mechanical damage, stay away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

KVV Cable (PVC) Fixed Installation Control Circuits

Type: GB/T 9330 – 2020 1ZR - KVV

1. Product Application

Specialized for signal transmission and control circuits in industrial automation systems, power distribution cabinets, mechanical equipment, and electrical control systems (rated voltage complies with relevant standards for control cables). Suitable for fixed installation in indoor, tunnel, or cable trench environments.

2. Product Ingredients

- Conductor: Stranded bare copper (IEC 60228, Class 5); core count: 2C~37C; cross-section range: 0.5mm²~2.5mm² (e.g., 1.0mm²: 19×0.25mm)

- Conductor OD per Core: Varies by cross-section (e.g., 0.75mm²: ≈0.98mm; 1.5mm²: ≈1.38mm)

- Inner Insulation: PVC resin; Color: Black/White/Red/Yellow/Green (color-coded for core identification)

- Insulation Thickness: Complies with control cable standards, min. thickness: 0.4mm (0.5mm²) ~ 0.6mm (2.5mm²)

- Outer Sheath: PVC resin; Color: Black (standard) / Gray (customizable); Sheath thickness: ≥0.8mm (2C×0.75mm²) ~ ≥1.2mm (10C×2.5mm²)

- Cable OD: Varies by core count & cross-section (e.g., 2C×1.0mm²: ≈6.2mm; 5C×1.5mm²: ≈8.5mm)

3. Properties

| Conductor DC Resistance (20℃) | ≤36.0Ω/km (0.5mm²); ≤22.8Ω/km (0.75mm²); ≤13.7Ω/km (1.5mm²) (complies with IEC 60228) |

| Insulation Resistance (20℃) | ≥500 MΩ km |

| Insulation Voltage Test | AC 2000V, 5min, no breakdown |

| Insulation/Sheath Tensile Strength | ≥12.0MPa (original); ≥8.0MPa (after thermal aging) |

| Insulation/Sheath Elongation at Break | ≥150% (original); ≥100% (after thermal aging) |

| Thermal Endurance | Long-term working temp: -10~70℃; Max. conductor temp under overload: 105℃ (short-term, ≤5s) |

| Flame Retardancy | Complies with IEC 60332-1-2 (vertical flame test) |

| Signal Transmission Performance | Capacitance between cores: ≤100nF/km; Attenuation: ≤1dB/km (at 1kHz) |

| Bending Radius | ≥6×cable OD (fixed installation); ≥8×cable OD (temporary movement) |

4. Features

- Rated Voltage: Common: 450/750V AC (complies with control cable standards)

- Service Life: ≥15 years (normal indoor industrial environment)

- Current Rating: 1.0mm²: 10A; 1.5mm²: 16A; 2.5mm²: 25A (free in air, per core)

- Signal Stability: Low capacitance & attenuation, suitable for accurate control signal transmission

- Protection Performance: Double-layer PVC protection, good moisture, oil, and abrasion resistance

- Current Rating Ambient Temperature: 30 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

It must be kept away from moisture, dust, and pollution, avoid mechanical damage, stay away from fire sources, and take measures to prevent rodents and insects.

Maintenance Instructions

- Regularly inspect the cable for any damage, especially the insulation layer or oxidation of the conductor.

- If any dust, oil stains, or other contaminants are found on the cable surface, promptly wipe clean with a clean cloth.

- If the cables have become damp, they should be dried before use.

- If the insulation layer of the cable has minor damage, it can be repaired using appropriate insulation tape. The cable must be replaced if it has any severe damage.

- Additionally, the cable should undergo regular insulation performance tests and related inspections to ensure that its performance meets requirements, based on the frequency of use and environmental conditions.

PE/PVC Power Cable (≤1.8/3kV) Low-Voltage Power Transmission in Fixed Installation Scenarios

Type: MT 818.12 - 2009 VLV22

1. Product Application

Specialized for power transmission and distribution in AC 50/60Hz low-to-medium voltage electrical systems with rated voltage ≤1.8/3kV, such as industrial parks, commercial complexes, residential communities, and small-scale power stations. Suitable for fixed installation in indoor, cable trench, pipe, or direct-burial environments (armored type only for direct burial).

2. Product Ingredients

- Conductor: Section range: 4mm²~240mm² (e.g., 10mm² copper conductor: 7×1.35mm)

- Conductor OD: Varies by cross-section & material (e.g., 25mm² copper: ≈6.0mm; 50mm² aluminum: ≈7.8mm)

- Inner Insulation: PE resin; Color: White/Translucent; Thickness: ≥1.2mm (10mm²) ~ ≥3.0mm (240mm²)

- Outer Sheath: PVC resin; Color: Black (standard); Thickness: ≥1.8mm (10mm²) ~ ≥4.0mm (240mm²)

- Armored Layer: Steel tape (for VV22/VLV22); Steel wire (for VV32/VLV32); Thickness: ≥0.3mm (steel tape)

- Cable OD: Varies by structure (e.g., VV 1×25mm²: ≈12.5mm; VV22 1×50mm²: ≈18.2mm)

3. Properties

| Conductor DC Resistance (20℃) | Copper: ≤4.43Ω/km (10mm²); ≤1.83Ω/km (25mm²); Aluminum: ≤7.39Ω/km (10mm²) (complies with IEC 60228) |

| Insulation Resistance (20℃) | ≥1000MΩ·km |

| AC Voltage Test | 3.5kV, 5min, no breakdown (rated voltage 1.8/3kV) |

| Insulation Tensile Strength | ≥12.0MPa (original); ≥8.0MPa (after thermal aging) |

| Sheath Elongation at Break | ≥150% (original); ≥100% (after thermal aging) |

| Thermal Endurance | Long-term working temp: -20~70℃; Max. conductor temp under short circuit: 250℃ (≤5s) |

| Flame Retardancy | Complies with IEC 60332-1-2 (vertical flame test); Flame-retardant type (ZR-) complies with IEC 60332-3-22 |

| Bending Radius | Non-armored: ≥12×cable OD; Armored: ≥20×cable OD (fixed installation) |

4. Features

- Rated Voltage: ≤1.8/3kV AC (Um=3kV)

- Service Life: ≥20 years (normal indoor/outdoor environment)

- Current Rating: VV 1×25mm²: 115A; VV 1×50mm²: 165A; VLV 1×50mm²: 130A (free in air)

- Protection Performance: PE insulation (good electrical insulation) + PVC sheath (moisture/oil resistance); armored type adds mechanical impact resistance

- Cost-Effectiveness: Aluminum-core type (VLV series) has lower cost, suitable for large-span power transmission with low load density

- Current Rating Ambient Temperature: 30 ℃

- Installation method: Free in air, On surface, without direct contact, Cable surfaces are adjacent to each other

- Current rating: 55A, 52A, 48A

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total Length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384,000m |

| 40ft | Wooden box | 100m | 192Roll / 768,000m |

6. Storage

To ensure safe operation, store the equipment in dry, clean conditions away from corrosive substances, impact, heat sources and pests.

Routine Maintenance Steps

- Perform daily checks by inspecting for deformation (cabinet, doors, seals) and checking connections for looseness, overheating or rust. Keep surfaces clean by wiping dust and oil with a dry cloth.

- For troubleshooting, dry any damp parts (transformers, switches) before powering on; repair small insulation cracks and replace badly damaged parts.

- Regularly test electrical performance (insulation, voltage) based on usage and environment.

Oil-Immersed Transformer (Power grids)

Type: S20-10/0.4-(30~2500)kVA

1. Product Application

Suitable for AC 50Hz, 12kV and below power transmission and distribution systems, new energy like wind, solar and energy storage, smart grids, etc., for voltage and power conversion, distribution and control.

2. Product Ingredients

- Enclosure: Protection class IP63+, anti-corrosion

- High-voltage coil: T1 oxygen-free copper, multi-layer cylindrical winding

- Low-voltage coil: T1 copper foil/wire, stay curtain air channels

- Iron core: High permeability silicon steel, 5-step structure

- Transformer oil: High voltage-insulation plant mineral oil

3. Properties

| Rated voltage | HV:12kV; LV:0.4kV |

| Rated frequency | 50Hz |

| Rated capacity | 30~2500kVA |

| Temperature rise limit | Winding:≤65K (oil-immersed)/80K (dry-type); enclosure:≤30K |

| Protection degree | IP63 |

| Operating temperature | -25℃~+40℃ |

4. Features

- Earthquake resistance: 8 degrees

- Altitude: ≤1000m

- Noise level: ≤65dB

- Service life: ≥30 years

5. Packaging and Transportation

Packaging method: integrated/separate packaging, securely fixed. Use

moisture-proof wooden boxes and plastic film (rust-proof, shock-proof). Internal

components are fixed to the base, and cushioning material is filled between the

equipment and the packaging box (or transport frame). Clear warning labels are

affixed.

Avoid outdoor storage; prevent collisions and overturning. Lifting operations must

follow marked instructions; lift each unit individually and secure firmly.

Supports sea, land, and air transportation; keep away from heat sources.

| Container | Set/wooden box | 20ft | 40ft |

|---|---|---|---|

| Unit | 5unit | 5unit | 10unit |

6. Storage

To ensure safe operation, store the equipment in dry, clean conditions away from corrosive substances, impact, heat sources and pests.

Routine Maintenance Steps

- Perform daily checks by inspecting for deformation (cabinet, doors, seals) and checking connections for looseness, overheating or rust. Keep surfaces clean by wiping dust and oil with a dry cloth.

- For troubleshooting, dry any damp parts (transformers, switches) before powering on; repair small insulation cracks and replace badly damaged parts.

- Regularly test electrical performance (insulation, voltage) based on usage and environment.

Dry-Type Transformer (Power distribution)

Type: SCB14-10/0.4-(30~2500)KVA

1. Product Application

Applied in AC 50Hz, 12kV and below power distribution systems for power conversion, distribution and control.

2. Product Ingredients

- Enclosure: Aluminum alloy / Stainless steel

- High-voltage coil: Oxygen-free copper (T1)

- Low-voltage coil: Copper foil / Copper wire (T1)

- Iron core: Silicon steel

- Busbar system: Silent fan

3. Properties

| Rated voltage | HV:10kV; LV:0.4kV |

| Rated frequency | 50Hz |

| Rated capacity | 30~2500kVA |

| Temperature rise limit | Winding: ≤65K (oil-immersed); enclosure: ≤30K |

| Protection degree | IP2X |

| Operating temperature | -25℃~+40℃ |

4. Features

- Earthquake resistance: 8 degrees

- Altitude: ≤1000m

- Noise level: ≤65dB

- Service life: ≥30 years

5. Packaging and Transportation

Packaging method: integrated/separate packaging, securely fixed. Use

moisture-proof wooden boxes and plastic film (rust-proof, shock-proof). Internal

components are fixed to the base, and cushioning material is filled between the

equipment and the packaging box (or transport frame). Clear warning labels are

affixed.

Avoid outdoor storage; prevent collisions and overturning. Lifting operations must

follow marked instructions; lift each unit individually and secure firmly.

Supports sea, land, and air transportation; keep away from heat sources.

| Container | Set/wooden box | 20ft | 40ft |

|---|---|---|---|

| Unit | 4unit | 4unit | 8unit |

6. Storage

To ensure safe operation, store the equipment in dry, clean conditions away from corrosive substances, impact, heat sources and pests.

Routine Maintenance Steps

- Perform daily checks by inspecting for deformation (cabinet, doors, seals) and checking connections for looseness, overheating or rust. Keep surfaces clean by wiping dust and oil with a dry cloth.

- For troubleshooting, dry any damp parts (transformers, switches) before powering on; repair small insulation cracks and replace badly damaged parts.

- Regularly test electrical performance (insulation, voltage) based on usage and environment.

Wire Harness and Connectors for New Energy Vehicles

Engineered to Customer Application Requirements

1. Product Application

As the medium of high-voltage power transmission, the high-voltage wiring harness

connects various components on the high-voltage system, transmits electrical

energy and shields external signal interference, and is the main carrier of power

output of new energy vehicles.

High voltage harness has the characteristics of high voltage, high current, high protection

level and anti-electromagnetic interference, is the neural network of new energy vehicle

high voltage system, is related to the vehicle performance and safety of the key components.

2. System Assembly

- Relay group assembly

- Rear door wire harness

- Engine wire harness

- LHR door transition harness

- Front bulkhead harness

- License lamp wire

- Floor wire harness

- Instrument panel harness

- LHF door wire harness

- Door switch wire

- RHF door wire harness

- Dome lamp wire

3. Product Component

- Automotive Wiring

- Conductor: annealed soft copper

- Insulation: PVC, XLPE, TPE

- Connector Housing: PA6, PA66, ABS, PBT, PP

- Terminal Body: brass or phosphor bronze

- Plating: tin-plated / silver-plated

4. Technical Parameters

| Voltage level | 12V/24V |

| Insulation resistance | ≥20MΩ |

| Corrosion resistance | Salt spray test needs to pass 96 hours |

| Protection degree | to reach IP67 |

5. Packaging and Transportation

Packaging materials should be moisture-proof, shock-proof, and

corrosion-resistant. Common materials include moisture-proof paper, foam, and

aluminum foil. Cable specifications, models, length, and other information should

be clearly marked on the outside of the packaging.

It's forbidden to store in open-air. During transportation, it must ensure that the

cable reel is not dropped from the top or is damaged mechanically. It can be transported

by truck, train, ship, and airplane.

| Container | Type | Total length (m) | Rolls |

|---|---|---|---|

| 20ft | Wooden box | 100m | 192Roll / 384000m |

| 40ft | Wooden box | 100m | 192Roll / 768000m |

6. Storage

Must be stored in a dry, clean, and pollution-free environment, avoiding moisture,

dust, and exposure to chemical pollutants.

Keep away from fire sources and take effective measures to prevent damage from rodents

and insects. Avoid mechanical squeezing, impact, and scratches from sharp objects;

ensure packaging remains intact.

Maintenance Instructions

- Regularly inspect the appearance of wiring harnesses and connectors, focusing on whether the insulation layer is damaged, the conductor is oxidized, or the connector terminals are corroded or deformed.

- Regularly inspect the appearance and insulation performance. Clean or replace immediately if damage, oxidation or contamination is found.

- Always disconnect power during operation for safety. Dispose of discarded components in accordance with environmental requirements.